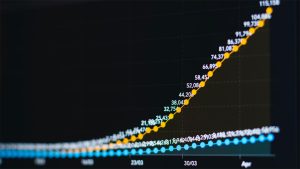

The coronavirus epidemic in the United States continues to accelerate. Much of the recent news has been about ongoing and unprecedented caseload increases in the large states of California, Texas and Florida.

While I pride myself on being a generalist, I do try to stick to my strengths when it comes to highly technical topics. I’m afraid that as regards coronavirus vaccines that isn’t possible. Biotechnology has veered into my lane, leaving me little choice but to return the favor.

The bottom line:

We’re likely to have a functional vaccine in the fourth quarter of 2020. As normally vaccines require a decade or more to develop, that’s truly moving at warp speed. But within this shiny nugget of good news seethes a swarm of complications and caveats.

Let’s start with the human trials. Vaccine testing proceeds in three phases.

Phase 1 is little more than a safety trial of 50 or so people to make sure the vaccine doesn’t make folks horribly ill. Phase 2 uses a few more people, but it is still little more than checking to be sure the vaccine’s components are not broken down in the body before they can do anything useful. (In the accelerated environment of the COVID crisis, many drug manufacturers are running Phases 1 and 2 concurrently.)

Phase 3 is where things get pathologically interesting. Thousands of people are injected and…released into the wild. The goal is for those injected to be confronted by the virus so that we know if A) the inoculated don’t get sick at all, B) they get sick but cannot spread the virus, C) they do not get sick but might still be able to spread the virus, D) if they get sick but suffer less intense symptoms, E) the proto-vaccine it does nothing at all, or God forbid F) the proto-vaccine actually makes people more susceptible to the virus. F sometimes happens. F sucks.

Point being Phase 3 is where the rubber hits the road. Right now, eight of the over 100 vaccines that are under development globally are in Phase 3 trials. The Russians decided they didn’t need Phase 3 and have gone ahead and approved theirs for general use. (I’m not saying this is preordained to end in unfettered horror, but I’m also not saying now would be a bad time to watch Moscow for signs of the zombie apocalypse.)

When I say we’ll have a functional vaccine in the fourth quarter, what I mean specifically is that at least one of these 100 (most likely one of the eight) will have made it through Phase 3 with a result of A, B, C or D. All those outcomes are considered good enough to qualify as “successful”. But even if the vaccine comes in on September 1 with a solid “A”, that hardly means the COVID-19 crisis is over. If anything, that’s only the start of the road back to normal.

The next piece of the process is manufacturing. Some vaccines require live virus which must be grown en masse. That, obviously, requires significant biohazard lab expansions. Some just require snippets of RNA and can be produced in days. Probably. Some of the newer RNA techniques – like that for the Moderna candidate – are only now being used for human vaccines for the first time. Some use a big vat of yeast which can be prepped in hours. Some need an extract from a specific sort of Chilean soapbark tree that can only be harvested in the Southern Hemisphere’s summer. I can’t give you a production timeline because each vaccine uses a different process, the materials and processes are proprietary, and we do not yet know which one will work.

Then there’s distribution. Here I’m not too worried. Every country already has a built-in, tried-and-true system for the mass distribution and application of vaccines. Think biannual flu shots. I’ve always found the logistics that make the flu shot possible to be magical. I’ve not gotten the flu in over a decade. (Go me!)

But that hardly means there cannot be distribution complications. Some vaccines require refrigeration. Some require freezing. Based on components and temperature requirements, each has their own peculiar demands for glass vials and syringes – and even stoppers. Use the wrong packaging or transport method, and you’ve just wasted months of work and millions of doses.

Finally, there’s the far-from-minor issues of efficacy and longevity of protection. Not all vaccines for the same bug are created equal. Some might require a higher dose or even multiple doses to achieve some semblance of protection. For example, that biannual flu shot I’m so fond of requires a higher concentration for the elderly in order to stimulate an immune response. The CanSino candidate might not work in the elderly at all. If two doses are required – which is currently the best guess for the Jenna/Oxford candidate – we’ll need twice the production capacity.

If the vaccine triggers a strong immune response – like the BioNTech/Pfizer candidate appears to – that’s great! But if protection only lasts a few months, we’ll need to mass produce the vaccine for global use forever…or at least until we grind the virus out of the population. (Keep in mind humanity has only actually eliminated one virus – smallpox – to the point we could stop immunizations.)

While things can and will change week by week, at present the Jenna/Oxford candidate seems to be on track to be deemed “successful” first, while the Moderna candidate faces the fewest manufacturing challenges, while the BioNTech/Pfizer candidate appears to be the most effective. China’s CanSino is a bit of a black box, but it will likely be significantly delayed. Determining a vaccine candidate’s effectiveness requires exposing the inoculated to the virus, and the virus really isn’t in circulation in China any longer. That forces the Chinese to convince other nations to be their guinea pigs. *wince*

The dream vaccine would be a one-shot vaccine delivered via nasal inhalant (no syringe required!), be made from yeast, safe to store at room temperature, grant 100% immunity, and last a lifetime. Assuming for the moment such is possible, we’re not very likely to hit the bull’s eye on the first try.

Instead it’s more than merely possible the first “successful” vaccine to market will be one that requires two shots given two months apart, is fabricated using the pancreatic fluids of a llama, only lessens the impact of COVID rather than outright preventing it, must be frozen for transport, and must be re-administered every six months. If that’s the one that wins the race, you can bet we’ll keep developing alternatives until we find something better.

But while we develop better alternatives, we’ll hit another trough. Manufacturers of glass and syringes and stoppers are holding their breath, planning to surge output to whichever candidate proves successful first. Should the first across the finish line not be the ideal vaccine, we will then need to retool everything to supply the manufacturing process for a better vaccine once it proves that it is indeed better. Based on the product requirements, there will be a delay of weeks to months.

Which vaccine is deemed “successful” first matters. No matter which candidate proves successful, global vaccine manufacturing for a fundamentally new cocktail is unlikely to be able to generate more than 100 million doses in calendar year 2020, with an additional one billion to two billion in 2021. If the “winning” mix requires two doses or biannual injections, cut the number of people who can be immunized in half. If it requires two doses and biannual injections, then by the end of 2021 there might not even be enough doses for all American citizens. To maximize their chances of getting what they need, the Americans have thrown $1 billion plus at each of the three lead candidates, complete with pending orders for at least 100 million doses.

That’s smart, but it hardly guarantees success – and the stakes are high. For one, the United States has not only failed to eradicate the novel coronavirus, it has largely failed at even the most basic of mitigation measures. We’ve collectively placed all our chips on securing a vaccine.

For two, not all doses of the “winning” formula will be produced in the United States, and other countries will want doses for their own people. The United Kingdom is a biotech leader who isn’t faring much better than the United States. The Germans are biotech leaders…and health nuts. Should doses be produced in India or China or Brazil, do you really think New Delhi or Beijing or Brasilia will prioritize shipments to the United States? Would you want them to??

So yes, we’ll likely identify something “successful” at some point in the fourth quarter of 2020, but add in the time lags for manufacturing and distribution, and the almost-certainty that Americans will have to share some doses with other nations, and the absolute most optimistic schedule possible for achieving mass inoculation of the American population won’t be until at least April 2021.

If you enjoy our free newsletters, the team at Zeihan on Geopolitics asks you to consider donating to Feeding America.

The economic lockdowns in the wake of COVID-19 left many without jobs and additional tens of millions of people, including children, without reliable food. Feeding America works with food manufacturers and suppliers to provide meals for those in need and provides direct support to America’s food banks.

Food pantries are facing declining donations from grocery stores with stretched supply chains. At the same time, they are doing what they can to quickly scale their operations to meet demand. But they need donations – they need cash – to do so now.

Feeding America is a great way to help in difficult times.

The team at Zeihan on Geopolitics thanks you and hopes you continue to enjoy our work.