A couple more countries have joined the campaign trail to buildout their semiconductor industries: the United Arab Emirates and India. Let’s break down the different approaches to this buildout and how they might turn out.

The UAE is attempting to sweet-talk Samsung and Taiwan’s TSMC to build a semiconductor fab facility in places like Dubai and Abu Dhabi. In case you didn’t know, these places aren’t exactly known for their engineering expertise or labor forces capable of carrying out these complex operations; meaning these facilities would likely be filled with labor imported from South Asia. Basically they’re paying for the facility to be closer to home, but not actually doing any of the work.

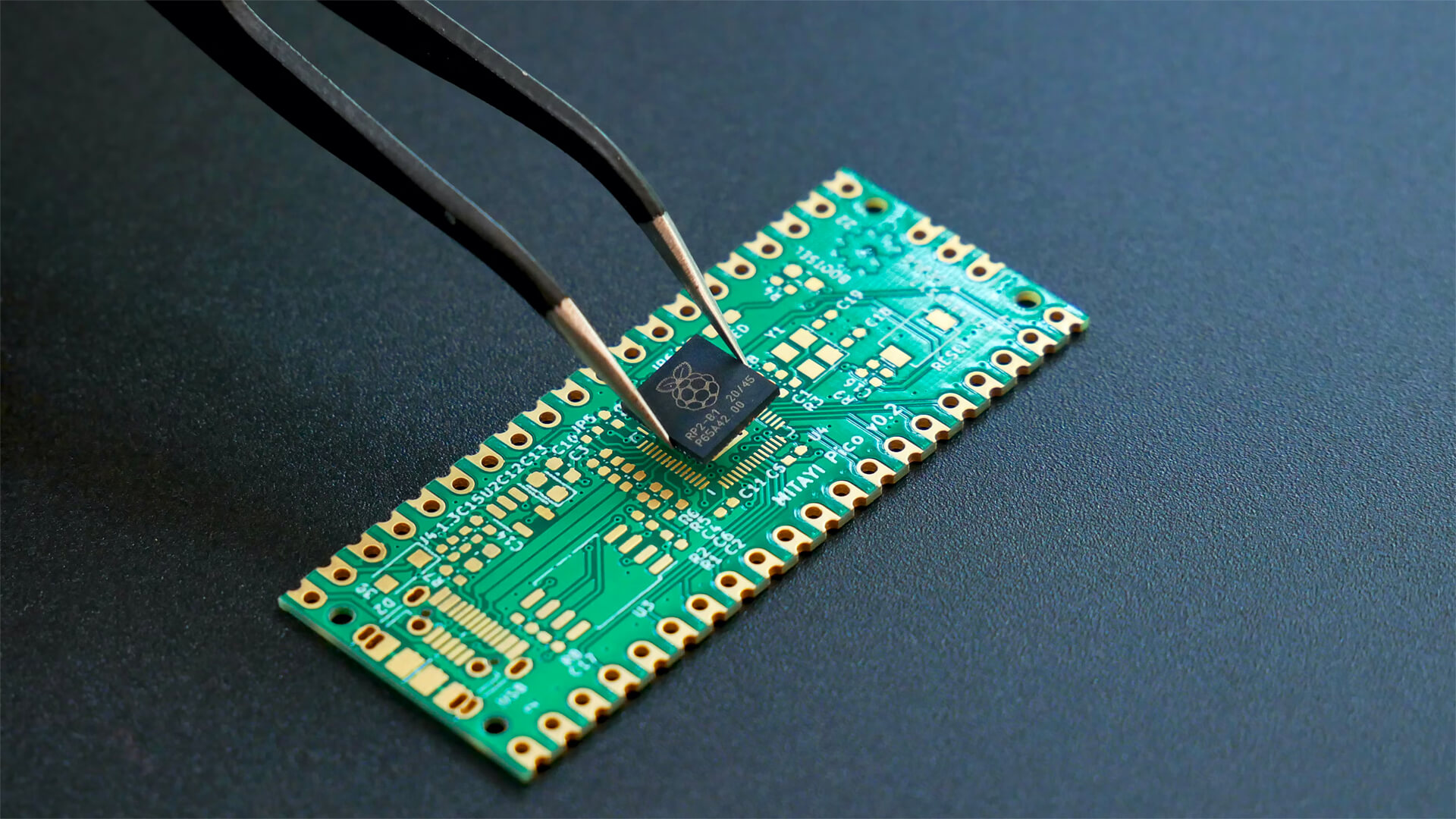

India, on the other hand, is working on a more sustainable model. Bringing together Powerchip and Tata, the Indians are focusing on producing less advanced chips. Don’t be fooled though, these chips and the fab facility where they are made would be vital for the growing tech sector in India. By using local labor and addressing the infrastructure issues associated, India’s approach leans towards functionality over prestige.

While both are attempting to localize semiconductor manufacturing, the UAE and India have different approaches that will likely have very different results.

Here at Zeihan on Geopolitics, our chosen charity partner is MedShare. They provide emergency medical services to communities in need, with a very heavy emphasis on locations facing acute crises. Medshare operates right in the thick of it, so we can be sure that every cent of our donation is not simply going directly to where help is needed most, but our donations serve as a force multiplier for a system already in existence.

If you sign up for our Patreon page in the month of October, the proceeds from your subscription for the remainder of 2024 will be donated directly to MedShare. So, you can get our all of the perks of joining the Patreon AND support a good cause while you’re doing it.

We encourage you to sign up for the Patreon page at the link below.

Transcript

Hey, everybody. Peter Zeihan here. Coming to you from a hotel room where I’ve been laid low by a 24-hour flu problem. It’s like, hope it’s only 24 hours. Today we’re going to talk about semiconductors and something interesting that’s happening in the world of fabs. Dubai and Abu Dhabi, which are the two main cities in the United Arab Emirates and the Persian Gulf, are holding talks with Korea’s Samsung and Taiwan’s TSMC about building a fab facility in the Persian Gulf in the United Arab Emirates.

Normally, I would just wave this away because semiconductor fabs are one of the more, if not one of the most, complex manufacturing systems in the world. And there aren’t a lot of people in the Persian Gulf that can do basic math, much less, you know, high-end engineering. But I thought it might be worth exploring why it still might happen and what it would look like.

TSMC and Samsung are not the same. TSMC is what’s called a fab fabricator, and Samsung is more of a conglomerate, right? And so TSMC is part of an ecosystem that involves several thousand companies that come together to provide the materials and the designs, and TSMC simply puts it together. In fact, they don’t even design the managerial process.

What usually happens is a foreigner, typically someone who’s from Japan or the United States, designs a chip in league with the end user. And then that design is given to TSMC. And then that designer typically goes out and sources all of the materials that are necessary to make the chip, ensures that they’re high quality, and then brings them to TSMC themselves.

It’s a little bit oversimplification, but think of TSMC as the world’s best direction followers. They don’t have a lot of intellectual capital in terms of interpreting the designs. That’s all managed by the American or the Japanese guy. Instead, they have an ecosystem of hundreds of companies within Taiwan who then take individual pieces of the design and figure out how to make it most effectively.

And then all of that information is combined under the American or Japanese person’s tutelage in order to provide a very, very specific series of instructions for TSMC, which they then follow. I’m not saying this to suggest that TSMC isn’t good at what they do. Oh my God, they’re the world’s best. But the really high value-added isn’t done in the fab; it’s done outside the fab by others. Samsung in Korea is a little bit different. They’re more of a conglomerate. They have a design house, and they handle more of the instruction-building themselves. But still, these two companies, Samsung and TSMC, are two of only three companies on the planet that can make the high-end chips that are smaller than five nanometers.

The third one is Intel in the United States, which is a little bit more similar to Samsung than TSMC. Anyway, the point of all of this is it’s really, really complicated, requires a lot of really, really smart people who are really, really good at math and engineering. And the Persian Gulf is not known for having any of that.

UAE is basically a financial center because things, concepts like interest, are illegal under Islamic law. So UAE has found a way to kind of do an end run around Sharia laws and the such. And basically, if you’re in the Middle East and you want your money to actually earn something, you bring it to Dubai. And then Dubai does the investing, usually via third-party nationals.

So the idea that you could have a high-end fab in UAE using local labor is hilarious. So it wouldn’t use local labor. The UAE is basically a slave state, and they bring in people from other countries to do all of their work, most notably South Asians. And so if, if, if you get a fab facility operating in the UAE, it’s going to be manned almost exclusively by Indians.

And which brings me to the next point that India’s getting the fab. But they’re not doing what the Emiratis are doing and trying to get the world’s best, so it’s kind of a feather in the cap. No, they’re just going for functionality. So the company Powerchip is partnering with Tata, which is an Indian industrial conglomerate, to build a fab facility that will not make the high-end chips.

The best chips they will make will be 28 nanometers, which is what you are going to see in your typical car, going down to 110 nanometers, which is Internet of Things sort of quality. Nothing particularly sexy. But India, to this point, has not had a single fab operating in the country. It’s a problem of not labor or labor quality.

It’s a problem of infrastructure. So if we have something in Dubai or Abu Dhabi, it’ll be the Emirates with their rock-solid power system, paying for everything and importing all of the labor and all the technology. And the only thing about it that will be Emirati will be the address. And then in India, we’ll have a system where the state will try to set up a better power grid locally to where this facility is going to be.

And then the local labor will be right there. So two very different models to get to two very different places, bringing different assets into play.