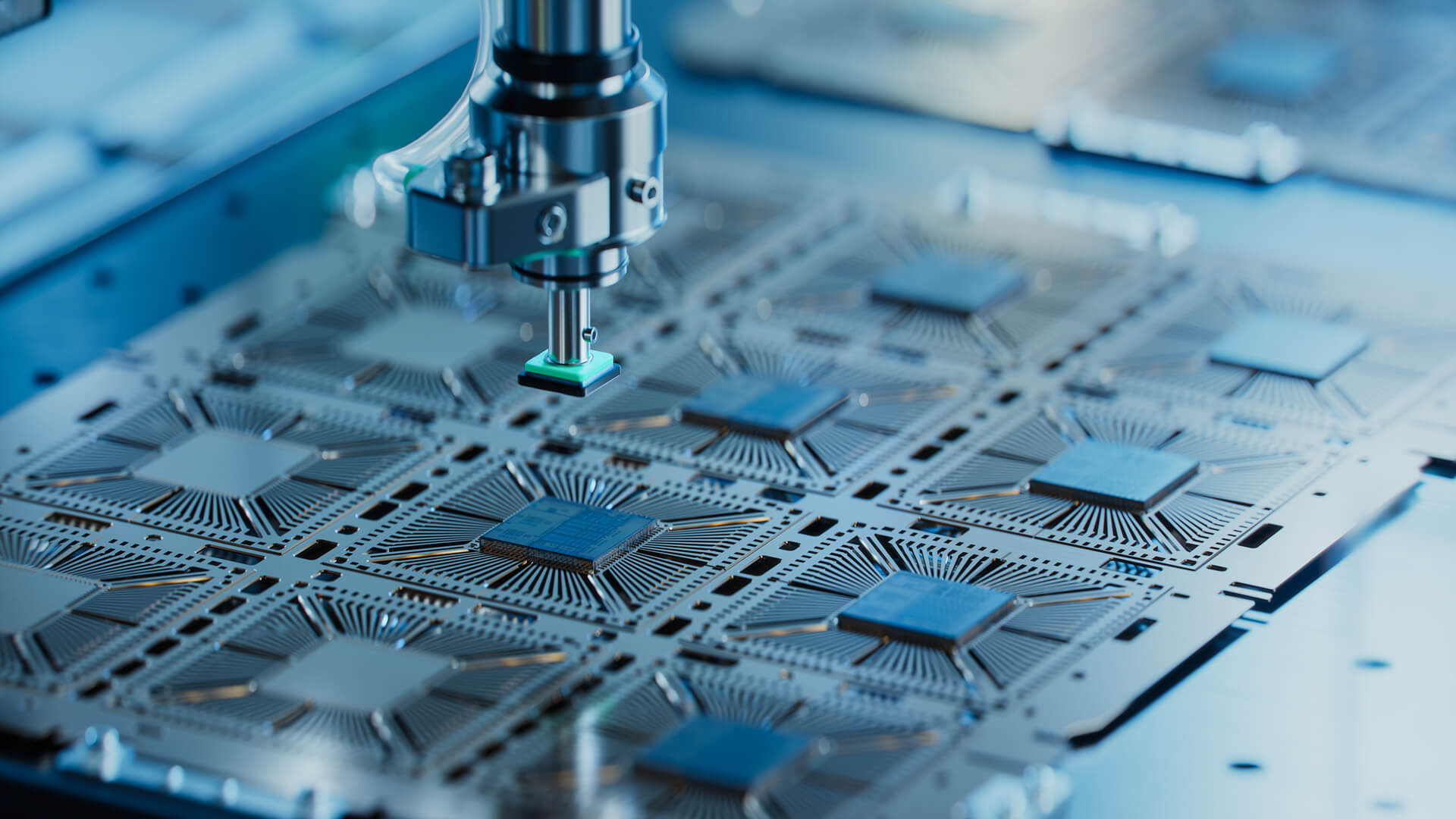

We’ve discussed how essential semiconductors are in our increasingly technological world, so here’s an update on ASML’s new High-NA EUV lithography machines.

ASML already builds the most advanced chipmaking tools, but these new models could enable chip designs at 1 nanometer or even smaller. Intel is betting on this new technology and could have mass manufacturing by the end of the decade, which would change the competitive landscape with TSMC. SK Hynix is similarly prepping new tech for these memory chips, which could give it the leg up on Samsung.

If it works, that is.

Transcript

Hey, all. Peter Zeihan here. Coming to you from Colorado, today we are taking a question from the Patreon crowd. Specifically, if I could give an update on what’s going on with the new EUV machines that are coming out of the Dutch from ASML. Background, for those of you who don’t follow this, ASML is the company that makes the lithography machines that make high end semiconductors possible.

Very, very, very short version. It’s basically a machine about the size of a bus that makes a tiny little laser that operates at an accuracy that is smaller than a DNA strand and allows you to etch semiconductors at the nanometer level. EUV in its current form can go down to about three nanometers below that. It basically loses coherence. And so there’s a new machine called a high numerical aperture that, in theory, can take you down to one nanometer and even below.

And the idea is that the smaller you can edge your transistors, the more processing power you can cram onto a piece of silicon. And the more powerful the semiconductor on the other side can be. So EUV is a technology that’s been around since 2012, 2014 somewhere in there. And it was grabbed by what was then the industry underdog, which was TSMC in Taiwan.

And over the course of the next several years, they leaped ahead of who the old industry leader had been. And that was America’s Intel. Now we’ve got the flip side. TSMC is reserving the right to maybe buy one of these new machines, the high end machines. But it is Intel that’s now betting their future on the new technology, hoping that they can repeat the feat that TSMC did and once again become the world leader.

They have two of those machines are at their Hillsboro facility. They’re currently cranking out about. Well, their goal is to crank out about 10,000 chips a month, which is very, very, very small scale. They’re very much still in the testing phase. And it is just simply too soon to know if a this technology will work and be what its effects will be, and the be what its effects will be is really the question here.

When we went from duv. Deep ultraviolet, which was the old technology, this is what the Chinese have still to EUV, which is now the standard for premium chips.

The nature of semiconductor has changed because it wasn’t just about cramming more into less space, it was making them more energy efficient, was doing things with the architecture eventually leading to stacked chips.

And so it wasn’t just a linear jump. And there’s possibility that with high end A, we will have another linear jump that will leave all the chips that that we make today behind, but we don’t know that until we have our first mass manufacturing run, that at the soonest will be at the end of calendar year 2026, and that will just be with a couple machines.

Then we will have to have the industrial build out to build more of these machines. And these machines cost significantly more than a commercial aircraft. And then you’ll have to put them into the facilities and you have to start designing chips with the new hardware in mind.

So we probably wouldn’t have enough chips to matter in a way that would really move the needle technologically before 2029 or 2030. That’d be more than enough to revive Intel’s fortune. But, you know, if, if, if, if then, there is one other company in the world that is trying out this new technology.

It’s out of South Korea. It’s, SK Hynix, which is the company that makes the best, Dram chips. Those are memory chips. So what Intel does what TSMC does, those are GPUs. Those are processors. And those are important. But you have to pair it with a memory chip. And the Koreans excel at that. So as to the Dram side, SK Hynix is an industry leader, along with Samsung. They recently overtook Samsung in terms of total output, but in terms of quality, they’re pretty much neck and neck. And so now one of them has DNA and one of them doesn’t, if Na fails, I don’t think it’s going to be a disaster for this case.

SK Hynix are already a fantastic company. But Samsung does have more capital coming up behind them. But really, what’s going on in Korea is nothing compared to the drama between Intel and TSMC.

So let me give you a worst case. Best case for Intel. Worst case, this doesn’t work, in which case Intel is merely the second best chip manufacturer in the world. Americans get really pouty when they’re not number one, but this is still a solid company. And honestly, there are a lot more pieces of a supply chain under the hood of Intel than there are, in TSMC. The TSMC folks are great at what they do, but they basically follow the instructions that the designers gave them, and then they do the construction and everything in order to make the fabs function.

But the real high value added work is done somewhere else. Intel does more of these steps, more like a traditional conglomerate, which means that they’re probably not as efficient at any individual one of them. But of the 100,000 supply chain steps that go into making a high and semiconductor, they have a higher proportion of them under their roof, probably as many as a quarter.

So if this doesn’t work, Intel is fine. If it does work, TSMC doesn’t slip. They’re still making the chips that make today’s, silicon revolution possible. But then we also get a new frontier. The only caution I have is that currently, it takes a 100,000 supply chain steps to make a high end semiconductor with the high end American Aperture technology.

We really don’t know what that supply chain is going to look like, but it would be very strange if it was simpler. So this is already the industry that is the most overextended and dependent on globalization and threatened by Trump’s tariffs threatened by the fall of globalization and threatened by the demographic crash. The idea it’s going to be with us from ten years from now is a stretch.

But there is a little sliver of hope that, based on what the supply chains for high end are, maybe, maybe unlikely, but maybe it’ll be a little bit simpler. The first that we will have a good grip on, what that will look like will be in about a year.